- Whereas, 3D printing simulation and tool path generation are much easier. CAMotics aims to be a useful CNC simulation platform for the DIY and Open-Source community. CAMotics should serve the highly technical user but remain simple and user friendly enough to support less techie types as well.

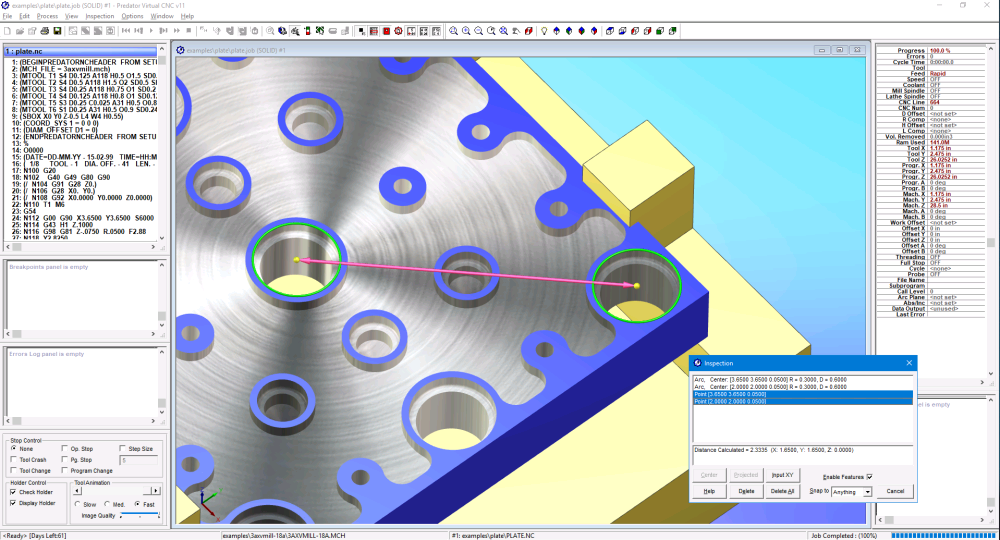

- This CNC software offers you a complete tool for programming the whole part at any external PC comfortably and productively. Thus, thanks to the simulator, you will be able to create, optimize and check the programs directly at a PC and then transfer them to the machine, consequently speeding up your work considerably.

Fusion 360 followed by Solidworks are the most popular CAD Software packages among CNC’ers according to CNCCookbook’s CAD Survey. Fusion 360 is free for non-business users and some small business users. What is the most popular CAM Software? Cnc Simulator free download - YS Flight Simulator, Flight Simulator X demo, Router Simulator, and many more programs.

Product Description

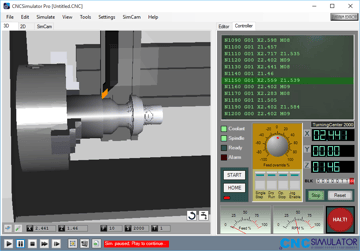

A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM-code (Fanuc System A).

The basis of the three-dimensional simulation model is a lathe machine with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery. Material processing is performed on two axes in the horizontal plane.

Field of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing».

The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard GM-code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment.

Type of target computing device and supported platform: IBM – compatible PC running Microsoft Windows, Apple Macintosh PC running MacOS, mobile devices based on Android and iOS operating systems. Additionally, program execution is possible in a web browser environment with support for HTML5 technology and hardware support for 3D graphics (WebGL technology).

Best Cnc Simulators

Graphics software uses OpenGL 2.0 components. The graphical user interface of the program is implemented in English and Russian.

Multi-platform support allows you to use the software on various computing devices, including interactive whiteboards, smartphones, tablet and desktop computers, which, in turn, increases the flexibility and mobility of the educational process, corresponding to the modern level of education informatization.

The simulator can be delivered with installation on one workplace (the user license with issue of registration keys) and with installation on unlimited number of workplaces (the corporate license for the organization).

Microsoft DirectX system components can be downloaded from the official website:

www.microsoft.com

Main Links:

License purchase procedure for one desktop devices based on Windows, MacOS, Linux:

5. Copy the license key received by email and paste it into the registration form inside the application.

The license for an unlimited number of devices is purchased for the organization under a license agreement. For more information, send a request via the contact form.

System Requirements

- CPU: Intel/AMD, at least 2 GHz;

- RAM: at least 1 GB;

- VRAM: at least 512 MB;

- Screen Resolution: at least 1024x768x32;

- DirectX version 9.0.c (for Windows OS);

- Standard keyboard and computer mouse with scroll wheel;

- Means of playing sound (audio speakers or headphones).

Here are some of the basic functions and features of Mach3 from the Mach3 website:

- Converts a standard PC to a fully featured, 6-axis CNC controller

- Allows direct import of DXF, BMP, JPG, and HPGL files through LazyCam

- Visual Gcode display

- Generates Gcode via LazyCam or Wizards

- Fully customizable interface

- Customizable M-Codes and Macros using VBscript

Mach3 is very popular among the Hobby CNC community.

Artsoft produces Mach3 software and has been around for some time. This software can be used as a fully functional CNC control or used as a CNC simulator for training, learning or testing CNC programs. This is also a great CNC control simulation software that you can install on your own PC computer. There are a couple tweaks to the configuration that you have to do before you can test it like modify the pinout configuration to bypass the emergency alarm that occurs on install, but that is about it.

Mach3 simulation allows you to test run all your CNC programs with the software and see how they run as well as look at a 3D view of the machining process or axis movements.

Best Cnc Simulator Free

Mach3 is a PC based control that is most commonly used on lower end CNC machinery. Wood working CNC machines tend to use these controls extensively.

Best Cnc Simulator Free

There is a free version that has some limitations but overall for CNC simulation the free version does what you need it to do. Tech support for Mach3 and previous versions like Mach2 and Mach1 is very good. Mach3 also has a great following and an extensive community of users throughout many CNC forums for further support needs.